Last Updated on January 6, 2026

How to Make Rum: A Distillers Guide

Learn Step-By-Step How To Make Your Own Homemade Rum

In this guide, we’re going to walk you through, step-by-step how to make rum from scratch. Differing from other spirits such as whiskey and vodka, rum has some pretty loosely defined production methods. These production methods vary widely between different locations and distillers creating rum. We’ll start by covering the basics of how to create rum in it’s simplest form and then go into more detail on the variety of different methods for creating the range of flavors of rum. All of the supplies you’ll need for distilling your own homemade rum can be found in our shop. If you’re more of a vodka distiller and drinker, then check out our guide on how to make vodka.

At Mile Hi Distilling, we love helping people who are passionate about spirits with the helpful guides and top quality moonshine stills and supplies. Learning how to make a great batch of rum requires a lot of attention to detail. So be sure to plan thoroughly and execute carefully to create the best rum possible. Let’s get started!

***Before we get started. It is illegal to distill spirits at home. This guide is meant as a hypothetical walk-through. Mile Hi Distilling doesn’t condone any illegal or illicit behavior and cannot be held responsible for the actions taken by any individuals not acting within the parameters of the law.***

Browse By Step. Click on any of these links to jump to the step you want to see:

A Short Background on The History of Rum

Getting Started: Picking Your Rum Wash Ingredients

How to Make Rum: Wash Recipe

Fermenting Your Rum Wash

Distilling

Collecting Your Distillate

Aging Your Rum

Conclusion

A Short Background on The History of Rum

Rum’s origin lies in the 17th century Caribbean Islands. The first distillation of rum took place on the sugarcane plantations, located on the island of Barbados. Slaves from the plantations discovered that by fermenting molasses, a byproduct of refining sugarcane, they could create alcohol. Then by distilling this alcoholic drink, they could create a concentrated and purer spirit. This is how modern rum was first created.

After the development of rum in the Caribbean islands, it quickly spread throughout the American Colonies. The very first rum distillery was established on Staten Island in 1664. This was the beginning of a very popular and prosperous industry for New England. Rum from Rhode Island was even accepted as a currency within European trading networks.

A funny side note on the spirit. Rum became such a popular drink before the American Revolutionary War, that it’s estimated that every man, woman or child was drinking an average of 3.6 gallons of rum each year. That’s a lot of hooch!

The popularity of rum continued to grow exponentially after the war. George Washington even required a barrel of rum from Barbados for his 1789 inauguration into the presidency. But enough history, let’s get into how to craft your own homemade rum.

Getting Started: Picking Your Rum Wash Ingredients

Like we mentioned before, the process of creating rum can differ widely based on what location or culture you’re in. There are a few different ingredients that you can use to create your rum wash, but all of them stem from the same source. The sugarcane plant. Rum is predominately produced with usulphured molasses, a product resulting from refining the sugarcane plant. However, you can use raw cane sugar or sugarcane juice if you don’t happen to have molasses on hand. For this walkthrough guide, we’ll be using a combination of molasses and raw cane sugar to give our rum wash a sweeter caramel and vanilla character.

*Sulphured molasses has been treated with sulphur dioxide that acts as a preservative. This sulphuring process can leave the molasses with a chemical flavor so you’ll want to use an usulphured molasses for your wash.

Raw cane sugar is also used as a staple ingredient in rum. It’s a product of the sugarcane plant being harvested and processed.

How to Make Rum: Wash Recipe

Base Ingredients & Materials

- 6.5 Gallons of Water

- 1 Gallon of BlackStrap Molasses

- 8 Pounds of Raw Cane Sugar

- Professional Rum Turbo Yeast

- Brew Pot

- Heat Source

- Thermometer

- Long Spoon

Sugar/Molasses Wash Procedure

- Place your brew pot on its heat source and pour in 5.5 gallons of water.

- Heat water to 125 °F.

- Stir in Raw Cane Sugar and Molasses and stir with long spoon until completely dissolved. (you may have to stir for a while to get your molasses to fully dissolve)

- Once the Molasses and Sugar are fully dissolved pour in 1 gallon of cold water to bring the temperature of the wash down.

- Check temperature and stir wash for 30 seconds every 5 minutes until the temperature cools to 80 °F. (This process can take several hours on its own, but can be sped up significantly with the use of an immersion cooler.

- When the wash has cooled to 80 °F, add rum turbo yeast.

- Aerate the wash by dumping it back and forth between two separate containers for 5 minutes.

- Pour the wash into your fermentation bucket. We carry complete fermentation kits for these as well as the materials to produce your own. It is important to have the bucket, cap, and air-lock. A spigot also makes for easier pouring.

- Seal your fermentation bucket with the air-lock and store in a dark place around 75 °F – 80 °F.

Fermenting Your Rum Wash

Materials

- Cheese Cloth

- pH Meter (Advanced)

- Citric Acid

- Hydrometer

Fermentation

Rum washes that include molasses will differ slightly in their fermentation process than those made with only raw cane sugar. A wash made purely with raw cane sugar will ferment for 3-7 days and when ready, no longer taste sweet or emit gas from the air-lock. The yeast can fully convert all of the sugars to alcohol in the wash.

A wash that includes molasses will take around 12 – 14 days to complete the fermentation stage, but when it’s ready, will still have a sweet taste. This is due to the yeast being unable to convert the caramelized sugars in the wash. You’ll know that the fermentation is complete when there is no gas coming out of the air-lock in your bucket kit.

To test the ABV (alcohol by volume) of your fermentation, you can use a hydrometer. If you’ve never used a hydrometer before, check out our ‘How To Use a Hydrometer‘ guide.

Straining

Once fermentation has completed, we’ll need to completely remove any solid material that may have formed. The solid material left over can lead to headaches if left in the wash. A cheesecloth is a great option for straining the wash before distillation.

(Advanced) Some distillers will test the pH of their wash. The ideal pH is 4.5 to 5.0. Use citric acid to bring the pH down and calcium carbonate to bring it up.

Distilling Your Rum

Materials

- Pot Still

- Still Burner

- Cleaning Products

- Easy Siphon

- Hydrometer

- Fermented and Strained Rum Wash

Great job! So far you’ve come along way and done all of the work necessary to actually produce your fermented rum wash. That rum wash currently contains some undesirable contents that you’ll need to separate out and dispose of. This is where the distillation step of making your own rum comes in. This process of distilling the fermented rum wash will make for a purer and more concentrated spirit. This step separates out all of the undesirable types alcohols such as acetaldehyde, acetone and methanol (which can cause blindness if consumed).

Prepping and Cleaning Your Pot Still

Don’t skip this step! Unfortunately many people do and it causes a subpar product in the end. If you aim to maximize the quality of your distilled spirit, then it’s all about attention to detail. You’ll want to start on prep-work by cleaning your still. If this is your first run ever, below is a great walkthrough of how to setup your pot or reflux still.

Even if you’ve cleaned the still after your last run and let it sit for a while, you will want to clean it again. If you’re just now learning how to make rum, or any other spirit for that matter, now is the time to really emphasize this so you can build in good habits to your distilling routine.

Next, you’ll add your rum wash into the still. We recommend using a siphon for this process. This is the best way to reduce the amount of sediment from your fermented rum wash getting into the still. Particles and sediments can cause the distillation to burn and ruin your product so be diligent in this step.

Running Your Pot Still

It’s now time to fire up that pot still! Ensure that your still is properly set for this step. Secure all clamps and domes and make sure condensers are properly attached, as well as any hoses. Next, you’ll turn on the heat source and start raising the temperature of your rum wash. You’ll want to run the rum wash through two separate distillations. During the first, you’ll collect the entire distillate without separating the heads, hearts and tails. That will be done during the second round of distillation.

If using a condenser, turn on the water when the boiler reaches 130 °F.

At about 168 °F the still will start producing. Increase the temperature to keep producing distillate.

Stop collecting distillate after it measures less than 20% ABV which you can measure using the hydrometer. Be sure to hold on to the remaining contents of the still as you’ll be adding it back in with your second distillation. This will add to the final flavor of the product. Dilute the first round distillate by 20% with water. Stir the mix thoroughly and add back into the still. Begin your second round of distillation.

Collecting Your Rum Distillate

Collecting your rum distillate is the most satisfying part of this entire process. This step is a mixture of art and science, as it takes an experienced distiller to get this process just right. That being said, don’t let this deter you if you’re a newcomer to distilling. Everything comes with practice and after you run a few batches with your still you’ll definitely be able to dial things in by taking notes and making the necessary changes.

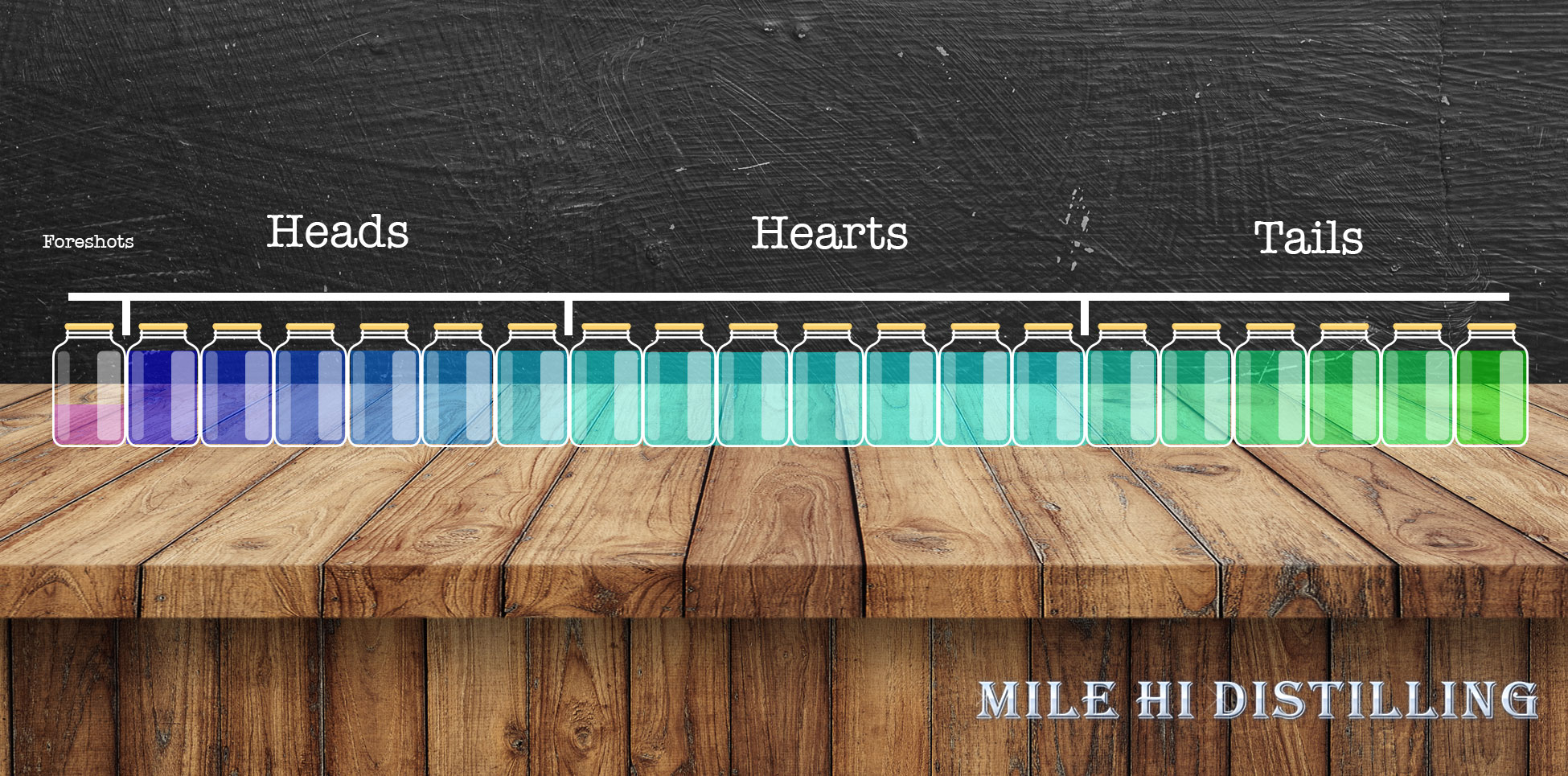

Foreshots

The first 5% of your run will consist of the foreshots. Foreshots contain methanol which is an extremely volatile and toxic alcohol. As a standard practice a good rule of thumb is to throw out the first 250 ml per 5 gallons as this part of your run will consist of these foreshots.

Do not consume this part of your run!

Be sure to isolate the foreshots thoroughly and throw them out. Consuming methanol can cause an array of issues including blindness.

Heads

The next 30% percent of your rum run is known as the heads. Similar to the foreshots, the heads of your run are filled with volatile alcohols. One of the staples of the heads is a particularly volatile alcohol known as acetone.

Acetone has a distinct, solvent-like smell, making its identification pretty easy to recognize. Drinking your heads won’t make you blind but they will leave you with the worst hangover of your life.

Like your foreshots, you’ll want to isolate these and throw them out.

*Note a great way of isolating both the foreshots and heads in your run is to bring your still to around 168 °F and keep it there for around 10 minutes. The alcohol produced during this duration will consist of only foreshots and heads. Once the condenser stops producing at 168 °F, you’ll know that you’ve collected all of the foreshots and heads of the run.

Hearts

If you’re following along with this guide, you have now officially gone from Googling “How to Make Rum” to actually making rum. The next 30% of your run will be the sweet spot of your rum run, the hearts. You’ll want to raise the temperature of your still to 175 °F to 180 °F range to start collecting this portion of your distillate.

You’ll notice the solvent smell of acetone taper off and a sweet-smelling ethanol come forward in your run. This is where a skillful distiller really shines. Maximizing high-quality hearts is a game of senses. You can recognize the hearts by their sweet and neutral flavor. *only taste a bit of the distillate on your finger. It’s not time for shot glasses yet my friend.

By accurately identifying where the acetone stops and the ethanol begins, a distiller maximizes their number of high quality jars of product. The main giveaways are the solvent smell of acetone and the sweet/smooth taste of ethanol.

Tails

The last 35% of your rum run will be the tails. You can recognize the tails by sight, smell and taste. You’ll see an oily film start to collect on the top of the distillate and be able to smell/taste a burnt type of flavor. The tails contain protein and carbohydrates from the wash that you don’t want in your final product.

Some tails have esters and other bi-products that can refine the character of your spirit and can actually add nice flavor to it. Be precise with your cuts and use your smell and taste to see what you like and don’t like in them.

Hold on to your tails and you can actually run them as their own wash in the future to pull out a bit more product.

Aging Your Rum

The results of aging rum can vary widely, depending on a few factors to consider. The type of barrel, whether charred or newer will greatly effect the flavors of the rum. A charred barrel will result in a darker and richer flavor, while a new barrel will deliver a lighter flavor. The amount of time that the rum is aged will also be a large factor in the final flavoring of the spirit. The longer you age your rum, the more time it has to soak up the flavors of the particular barrel you’re using. The area in which you are producing your rum also greatly affects the aging process. If you are in a more tropical climate, your rum will mature at a much higher rate. This is due to the amount of product lost due to evaporation. Always be sure to dilute your distillate to 50% before beginning the aging process.

White Rum

If your goal is to create a lighter white rum, than no aging is required. Simply dilute the drink with water to reach 45% and blend your mix thoroughly. Then bottle the spirit, and then leave for 3-4 days to let the tastes and flavors stabilize. You can also age your rum in a stainless steel barrel, which will let your rum age without darkening the color of the spirit.

Dark Rum

Many countries require that rum be aged after distillation for at least one year. This isn’t required by any means but it will definitely result in a darker and richer flavored rum. A good rule of thumb is to age your rum 6 to 18 months in a charred oak barrel or with oak chips to give your rum a distinct aged flavor. However long you decide to age your rum, you should blend your mix to ensure a consistent flavor. This is always the last step for any aged spirit prior to bottling.

Spiced Rum

After aging your rum, you can add much more flavoring by adding spices such as such as vanilla, peppercorns, cinnamon, allspice berries, cloves and nutmeg. This is where you can really experiment with the flavors and see what you like best. Be sure to add these spices in a separate container than the aging barrel used if you’d like to be able to experiment with different flavors for your next batch.

Conclusion

Congratulations! You have just made your own batch of delicious homemade rum. We hope this guide was helpful for you and you churned out a top-shelf spirit. Now comes the cleanup step. Be sure to wash everything thoroughly to ensure high-quality product in the future. Disassemble your still and store it in a cool, dry place.

Thank you for visiting Mile Hi Distilling, your one stop shop for all of your distilling needs. Don’t forget to check out our shop for any supplies or equipment you may need for any future distillations. We hope you enjoyed learning how to make rum with a raw cane sugar and molasses wash.

If you enjoyed this guide on how to make rum, check out our other guides on how to make moonshine and how to make vodka.

Let us know what you thought of this guide by leaving a comment or a star rating below.[kkstarratings]

The part about not using the tails is correct, however the part about tails containing proteins and carbohydrates is incorrect. Both substances are solids and cannot be distilled, period.

Tails are contaminated with fusel alcohols, a word derived from the German word for “bad” alcohol spirits. They only appear towards the end, after the hearts because they boil at a higher temperature. They can be nasty and smell like wet dog or cardboard.

Most whiskies and quite a few rums contain a small amount of tails – the earlier fraction – since they contain more flavor than the hearts. And when aged in a barrel chemical reactions happen that change their makeup, adding that delicious taste we associate with aged whiskey.

For a home distiller who lacks the time to barrel age, a small quantity of ethanol can be further extracted from further distillation. But be careful – once you taste tails, or smell that doggy smell, shut her down!

The part about not using the tails is correct, however the part about tails containing proteins and carbohydrates is incorrect. Both substances are solids and cannot be distilled, period.

Tails are contaminated with fusel alcohols, a word derived from the German word for “bad” alcohol spirits. They only appear towards the end, after the hearts because they boil at a higher temperature. They can be nasty and smell like wet dog or cardboard.

Most whiskies and quite a few rums contain a small amount of tails – the earlier fraction – since they contain more flavor than the hearts. And when aged in a barrel chemical reactions happen that change their makeup, adding that delicious taste we associate with aged whiskey.

For a home distiller who lacks the time to barrel age, a small quantity of ethanol can be further extracted from further distillation. But be careful – once you taste tails, or smell that doggy smell, shut her down!